Maintenance & Technical Operations Training

Deliver hands-on, repeatable simulations for complex maintenance, troubleshooting, and equipment operations—empowering teams to train safely, reduce downtime, and boost technical proficiency.

Hands-On Learning for High-Stakes Environments

When downtime costs thousands and errors risk lives, your workforce can’t afford to “learn on the job.” VR Vision’s immersive training simulations provide realistic, repeatable practice for complex and hazardous maintenance tasks—without taking assets offline or exposing workers to risk.

Our solutions are purpose-built for manufacturing, utilities, energy, and logistics teams, delivering measurable improvements in efficiency, accuracy, and safety. Whether you’re training new hires or re-certifying experienced technicians, our approach ensures consistency, compliance, and confidence across your technical workforce.

Transforming Complexity Into Competency

Maintenance and operations roles are often defined by complexity—multi-step procedures, safety interlocks, mechanical and electrical diagnostics, and environmental hazards. One missed step can mean equipment failure or serious injury.

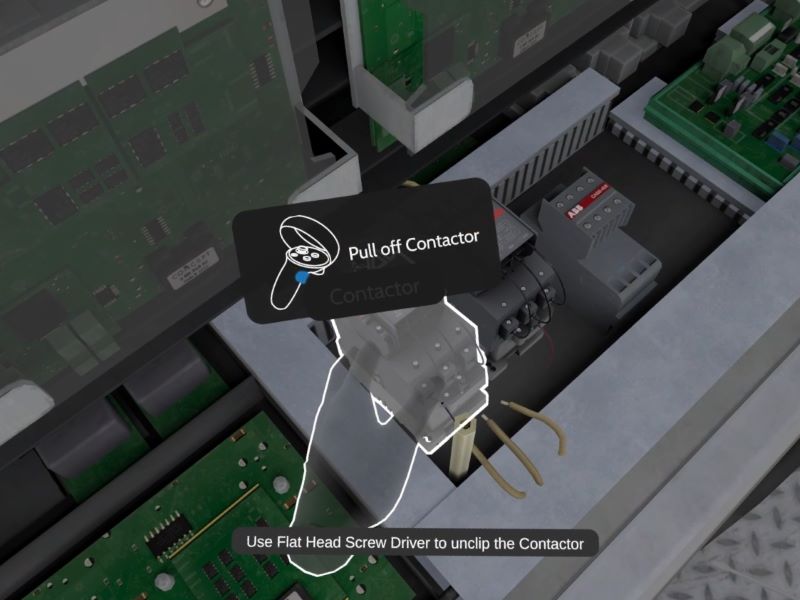

Our immersive modules turn these challenges into safe, interactive training experiences that drive muscle memory and decision-making under pressure. We cover critical workflows such as:

- Step-by-step equipment maintenance

Enable trainees to follow realistic procedures with in-VR guidance, interactive tools, and visual cues. - Troubleshooting electrical and mechanical systems

Train workers to diagnose faults using multimeters, megger testing, and logic-based problem solving. - Crane and bucket truck operation

Simulators replicate the behavior of rear-mounted cranes and POSI+ bucket trucks, training users on both manual and remote controls. - Lockout/Tagout (LOTO) procedures

Reinforce safety-critical processes like breaker isolation, equipment tagging, and hazard validation before maintenance begins.

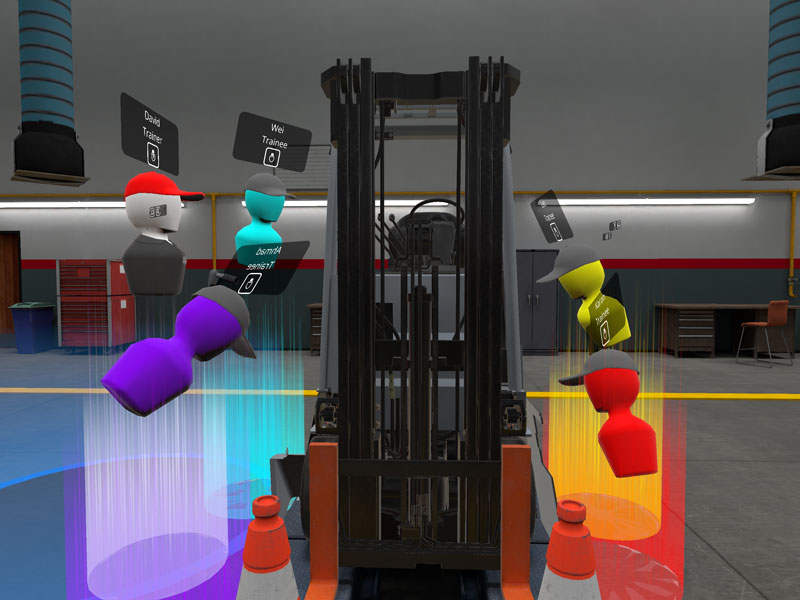

Every scenario includes multiple learning modes—education, evaluation, and multiplayer collaboration—giving trainers the flexibility to teach, assess, and reinforce as needed.

Why Industry Leaders Choose VR Vision

✅ Safer Training for High-Risk Tasks

Workers can rehearse high-voltage procedures, confined space rescues, or hazardous material interactions in a risk-free environment. This not only enhances confidence but also protects your bottom line by minimizing real-world errors.

✅ Reduced Downtime and Faster Onboarding

Companies like Toronto Hydro report up to 30% faster training time for switchgear technicians. Trainees can practice on virtual replicas of your real equipment before ever stepping foot on-site.

✅ Proven Gains in Knowledge Retention

Toyota achieved 50% improvement in technician retention for troubleshooting procedures using VR, while Siemens cut maintenance training time by 60% and workplace incidents by half.

✅ Measurable Cost Savings

Our VR training programs have helped enterprise clients save up to $1.5M annually by reducing travel costs, repeat instruction, and operational disruption.

Real-World Use Cases Across Industries

- Assembly line maintenance and calibration

- LOTO procedures for robotics and CNC equipment

- Forklift and crane operations

- Switchgear isolation and grounding

- Substation walkthroughs and SF6 gas handling

- Wind turbine troubleshooting (e.g., contactor, yaw motor, IGBT replacements)

- Bucket truck and crane training

- Vehicle and parts diagnostics

- Operator safety and hazard recognition

- Confined space entry and rescue

- Gas leak detection and remediation

- Valve control and safety compliance scenarios

Real-World Use Cases

Following a rigorous and structured approach to 360 video production and VR development, see some of our enterprise use cases.

Hydro One trained 2,000+ customer service reps using 360° onboarding, improving satisfaction and performance from day one.

Toyota Material Handling used VR to orient dealership techs across North America—cutting down on ramp-up time and travel expenses.

Avangrid integrated VR onboarding for field crews to reinforce safety procedures and reduce on-site incident risks during the first 90 days.

Powered by the Vision Portal™

Training isn’t complete without data. Our proprietary platform, Vision Portal, enables you to deploy, manage, and monitor VR training across locations and teams:

- Live VR session casting and control for trainers

- Advanced analytics including course completion, user-specific metrics, and time-to-competency tracking

- LMS integration for seamless reporting and compliance

- Remote assistance tools to guide trainees through procedures in real-time

Vision Portal ensures your investment scales with you—supporting unlimited devices and users across geographies.