The Workforce Has Changed Forever

The modern industrial workforce no longer gathers in a single room…it connects across continents. By 2026, more than half of all industrial and energy organizations operate with a hybrid or partially remote workforce. The shift toward decentralized teams has created new challenges for training and workforce development. Employees now work across multiple locations, time zones, and sometimes continents, yet they still need the same technical expertise, safety compliance, and operational consistency.

Traditional classroom or on-site training models struggle to keep up. They require travel, take equipment offline, and often vary in quality from site to site. Immersive learning through VR and AR (or XR) has changed that equation entirely.

With XR training, organizations can deliver standardized, hands-on instruction anywhere in the world. Technicians can practice procedures in virtual environments that replicate real-world complexity without the cost, logistics, or safety risks of physical setups. The result is a new era of workforce enablement where learning is accessible, measurable, and scalable from the cloud.

The Hybrid Reality of Industrial Training

Hybrid work no longer just applies to office staff. It now includes field technicians, plant operators, assemblers, and maintenance crews who need consistent, hands-on training. Energy companies manage assets across thousands of kilometers. Manufacturers operate distributed plants. Automotive suppliers train dealers and technicians in multiple markets.

The challenge is clear: how do you train everyone to the same standard when they are rarely in the same place?

Traditional training often involves sending instructors on-site, setting up live demonstrations, or hosting multi-day workshops that pull employees off the job. These approaches are expensive, inflexible, and slow to update when new procedures or regulations emerge.

Immersive VR and AR training solves this by allowing every learner to enter the same realistic environment virtually. Whether it is a lineman in Texas, a factory technician in Ontario, or an engineer in Munich, each person can experience the exact same training scenario. Every trainee learns from identical digital twins of equipment and environments, ensuring consistency across the global workforce.

For an in-depth breakdown of how immersive technology is transforming industrial learning, see our Ultimate Guide to Virtual Reality Training.

Why Immersive Learning Outperforms Traditional Methods

Virtual reality training replicates field experience without physical risk. When implemented at scale, it produces measurable results in safety, engagement, and retention.

At VR Vision, we have seen this firsthand. Toyota Material Handling uses our custom VR training to improve operational safety and consistency across dealerships and manufacturing facilities. The program saves them more than $1.5 million annually in training costs and has led to measurable improvements in compliance and performance.

The science supports these results. Studies show that learners retain up to 75% more information when they learn through immersive, experiential methods compared to traditional classroom sessions. VR enables muscle memory and cognitive recall by placing users in realistic, interactive environments that mimic actual work conditions. Across all of our enterprise clients, analytics from Vision Portal show an average 40% reduction in re-training time within the first year.

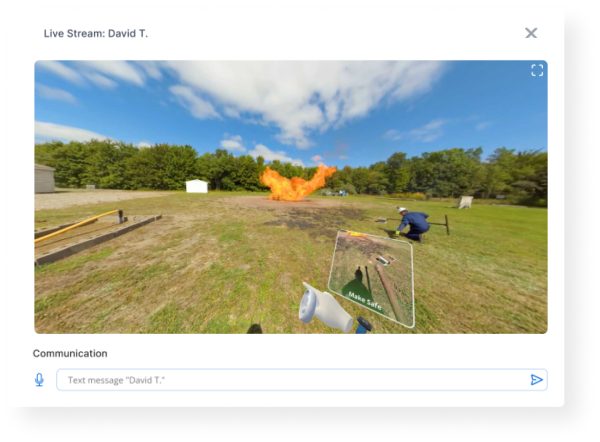

Another advantage is scalability. Through Vision Portal, trainers can deploy, monitor, and manage VR sessions in real time, no matter where their teams are located. They can see live headset feeds, skip steps, communicate with users, and collect analytics to evaluate performance. This makes remote coaching and skill assessment as seamless as if the trainer were in the same room.

How Remote and Hybrid Training Works in Practice

Energy and Utilities: Safety and Field Readiness

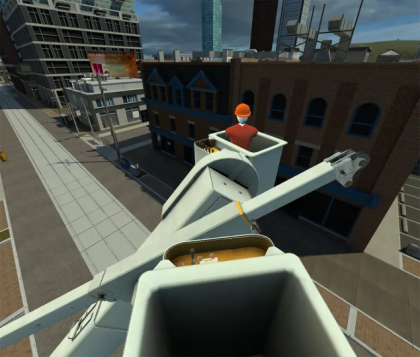

Utility companies face some of the most demanding training requirements in the world. Field technicians must understand high-voltage safety, emergency response, and complex switching procedures. VR training enables them to practice these skills in simulated environments that mirror the field—without the risk of injury or downtime.

Through Vision Portal, supervisors can oversee training sessions live, guide technicians remotely, and review analytics that show time-to-completion, number of errors, and skill progression. The result is faster certification, safer field performance, and improved compliance reporting.

Manufacturing: Global Consistency at Scale

For manufacturers and automotive companies, maintaining consistent quality across multiple plants is essential. VR training allows operators to learn new assembly procedures before equipment or parts arrive. This means every facility can ramp up production simultaneously, reducing rework and accelerating time to market.

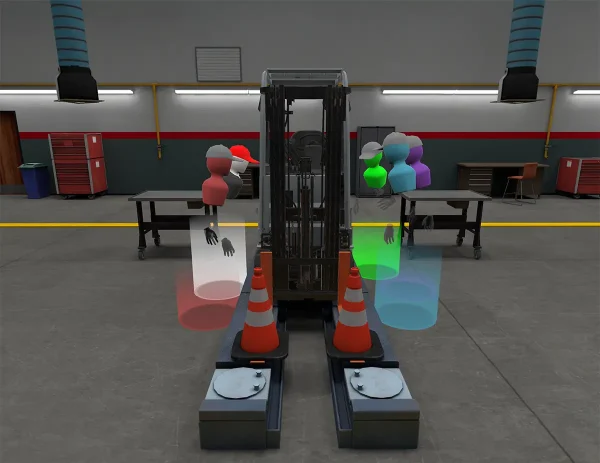

In one example, a global OEM trained teams across three continents using multiplayer VR simulations. Engineers collaborated in shared virtual environments to identify process improvements, troubleshoot assembly challenges, and validate new workflows before production began.

Industrial and Heavy Equipment: Process Mastery and Maintenance

Industrial operators, from oil and gas to mining, rely on complex equipment that demands precision and adherence to safety protocols. Using digital twins, employees can practice equipment startup, shutdown, or lockout/tagout procedures repeatedly until mastery.

Each session is recorded and analyzed through Vision Portal, giving training managers real-time visibility into skill development. When paired with an organization’s Learning Management System (LMS), this data becomes part of a complete compliance record.

For more practical examples and deployment frameworks, see our VR Training Implementation Playbook.

Building the Remote Training Ecosystem

The success of remote and hybrid crew training depends on the right infrastructure. At the center of this ecosystem is Vision Portal, VR Vision’s proprietary cloud platform.

Vision Portal enables organizations to:

- Launch and manage VR courses across unlimited devices and users

- Monitor live sessions and provide real-time feedback

- Access performance analytics across departments or job roles

- Integrate securely with existing LMS and Single Sign-On (SSO) systems

The platform supports Meta HMS, Microsoft Intune, and other major enterprise MDM providers like ArborXR and ManageXR, ensuring security and scalability for large deployments.

For even greater efficiency, Vision Portal integrates directly with advanced analytics and AI capabilities. This allows trainers to track usage, identify learning gaps, and adapt programs to specific roles or experience levels. The platform’s upcoming AI roadmap includes predictive skill scoring, automated feedback loops, and dynamic course recommendations.

When paired with VR Vision’s turnkey approach—including content creation, digital twin development, and change management—organizations can roll out fully operational XR programs in weeks rather than months.

Overcoming Common Barriers to Adoption

Even as the benefits become clear, some organizations hesitate to implement immersive training due to concerns about cost, logistics, or technology management. These barriers are easily addressed with the right strategy.

1. Cost and ROI

Hardware and software investments are now far more affordable than even two years ago. Devices like the Meta Quest 3 offer high-fidelity standalone performance at a fraction of previous costs. The long-term savings from reduced travel, facility time, and downtime often pay back the investment within a single fiscal year.

Our VR Training Cost Guide breaks down the full cost-benefit analysis for enterprise training.

2. Hardware Management and Security

VR Vision provides complete setup, device management, and security integration through Meta for Work and other enterprise platforms. Each headset can be locked, tracked, and updated remotely to maintain consistent deployment standards.

3. Change Management and User Adoption

Our onboarding process includes hands-on trainer workshops, technical training, and post-launch support. Trainers learn to navigate the Vision Portal, monitor learners, and interpret analytics to continuously improve training outcomes.

With a 99% employee retention rate and long-term client partnerships with Toyota, Siemens, and Coca-Cola, VR Vision’s track record demonstrates that immersive learning can be both accessible and scalable for even the most complex organizations.

The Future: AI, Digital Twins, and the Connected Workforce

The next generation of workforce training is already here. AI and digital twins are set to redefine how organizations measure, adapt, and evolve their training ecosystems.

By 2026, enterprises will use digital twins not just to train employees but to link training data with live operational systems. For example, an energy company could use VR simulations tied to IoT sensor data to predict when maintenance or safety retraining is required.

AI-driven analysis will identify performance gaps and automatically adjust learning content. Trainers will receive real-time insights on who is ready for promotion, who needs reinforcement, and which procedures cause the most repeated errors.

Mixed Reality headsets and spatial computing will also expand access to immersive training. Imagine an automotive engineer wearing lightweight digital display glasses to overlay digital instructions directly on a real assembly line. The same content used in VR for onboarding will guide live operations in the field.

Through continuous innovation in AI and XR, the connected workforce of 2026 will be smarter, safer, and more efficient than ever.

Conclusion: Training Without Boundaries

Hybrid work is no longer a challenge to overcome—it is an opportunity to innovate. With immersive learning, enterprises can train anyone, anywhere, with the same precision and consistency as on-site instruction.

By integrating VR Vision’s solutions, organizations can:

- Train distributed teams at scale

- Reduce costs and travel time

- Improve safety and compliance

- Measure every aspect of learning performance

- Future-proof their workforce for AI and automation

Immersive training transforms how enterprises upskill their teams in a connected, digital world. It removes location as a barrier and turns learning into a measurable strategic advantage.

Discover how VR Vision is helping global leaders in energy, manufacturing, and automotive industries redefine training for the hybrid era.

Book a Demo and see how you can train anywhere, anytime—with measurable impact through Vision Portal.